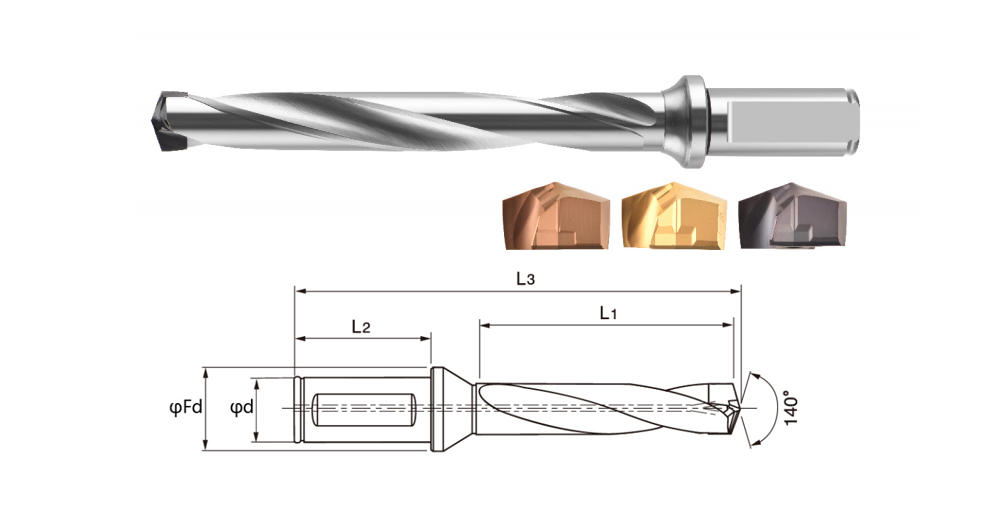

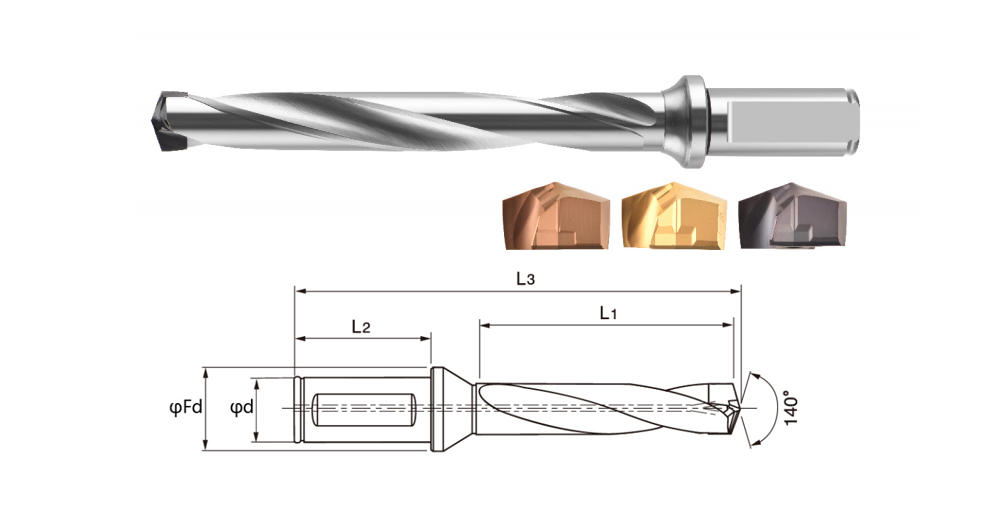

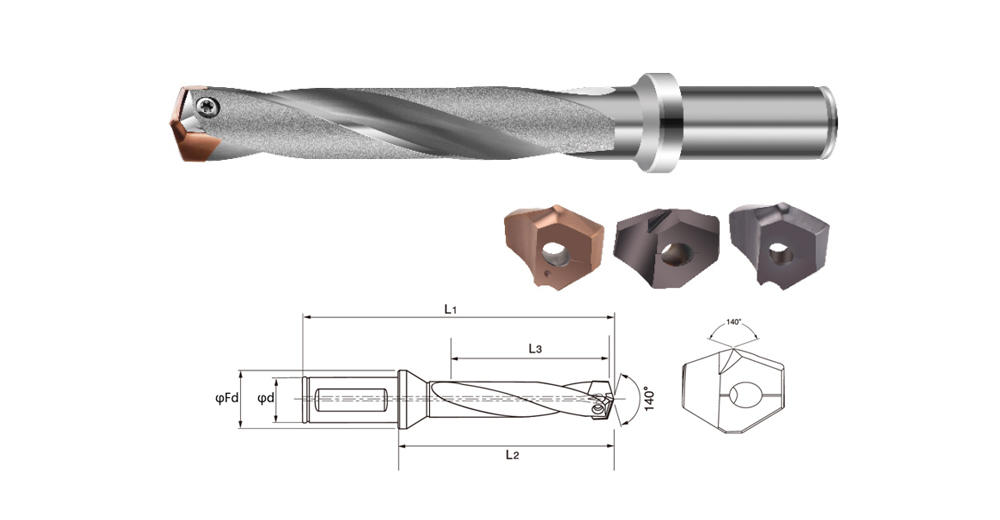

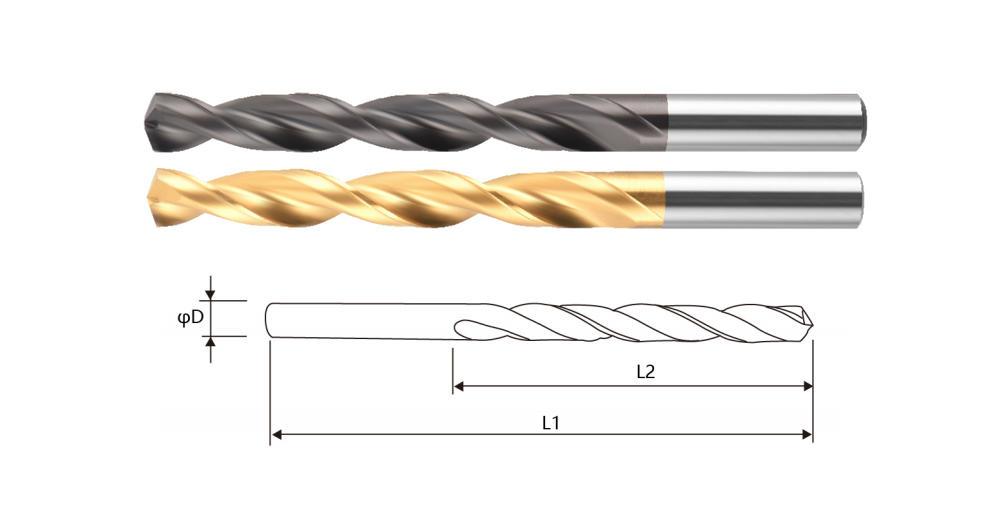

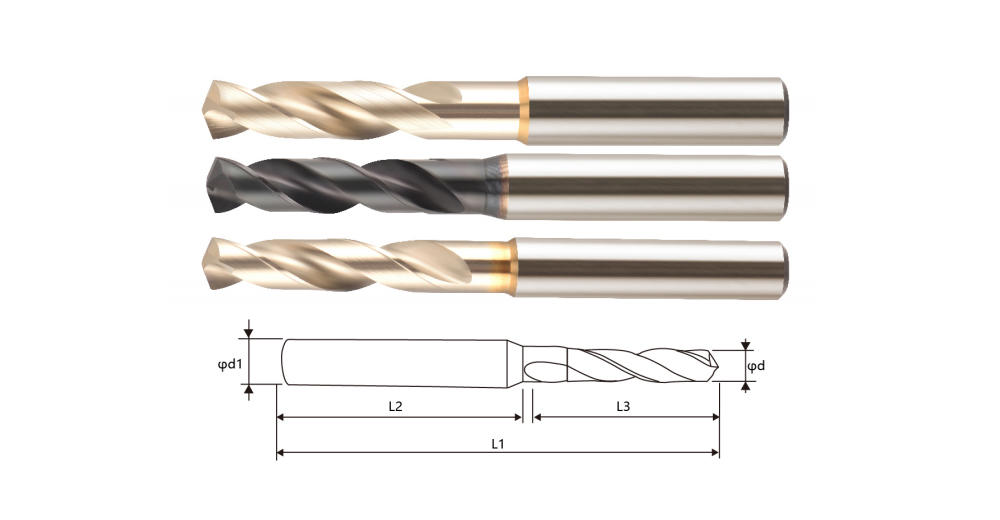

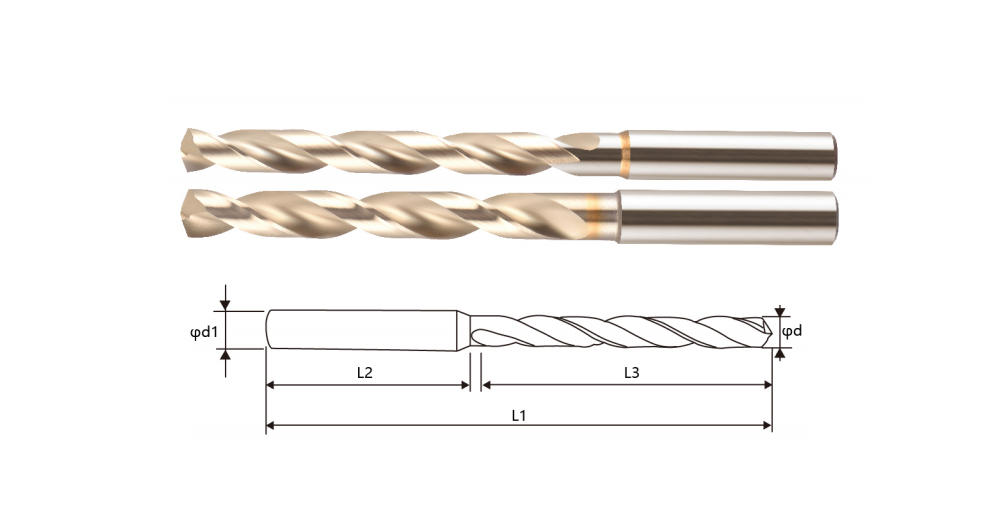

The increasing complexity of precision machining tasks has prompted a noticeable shift toward the adoption of advanced tooling. Among these, the High Performance Straight Shank Drill has seen expanded use across multiple industries. This type of drill offers users a consistent experience when cutting through a variety of hard and soft materials, making it a suitable option for operations that require both speed and accuracy. As manufacturing evolves, the growing interest in this tool reflects the demand for greater consistency and longer tool service life.

One of the main advantages of the High Performance Straight Shank Drill lies in its stable design, which provides balanced rotation and a firm grip within the chuck. These features contribute to reduced vibration, which in turn supports finer finishes and tighter tolerances. While earlier generations of straight shank drills focused on basic drilling capabilities, newer iterations have improved geometry and surface treatments, allowing for more efficient chip removal and better heat control during use.

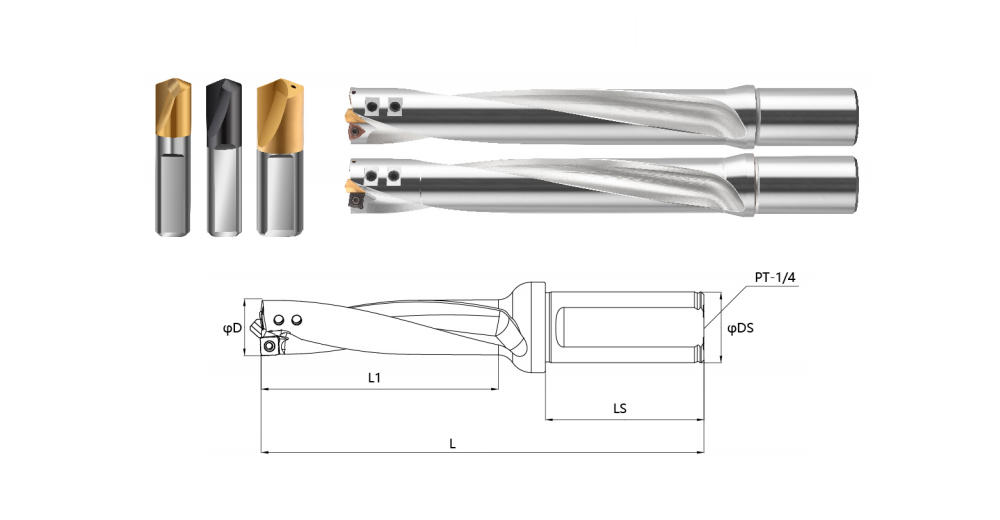

Parallel to this, the straight cutter tool has also gained popularity in workshops and production lines. Known for its direct cutting motion, the straight cutter tool is typically used for slotting, trimming, and shaping a wide range of materials. These tools are valued for their versatility, especially in applications where precision and simplicity are important. Engineers and technicians often pair straight shank drills with straight cutters in order to complete a full machining process using compatible tooling.

In recent years, users have reported improved workflow efficiency when incorporating both the High Performance Straight Shank Drill and the straight cutter tool into their setups. These tools complement each other well, particularly in small batch runs and custom part production, where reliability and repeatability play an essential role. Rather than relying on more complex multi-axis systems, many shops choose this combination for single-station operations.

Machining centers that integrate the High Performance Straight Shank Drill into their tool libraries frequently cite its usefulness in pilot hole creation and pre-threading operations. Its compatibility with automated and manual systems alike allows it to adapt to various production scales. The straightforward shank profile makes it easy to switch out between runs without requiring extensive calibration, saving time during changeovers.

Similarly, the straight cutter tool finds application in both vertical and horizontal milling machines. When selected with the correct material and geometry, it can perform light finishing tasks or roughing cuts depending on the need. This adaptability is one reason it continues to be a staple in cutting tool inventories. Toolmakers continue to explore material upgrades and edge designs to further enhance the lifespan and stability of this type of cutter.

The combination of the High Performance Straight Shank Drill and straight cutter tool creates a functional base for various machining tasks, from basic drilling to detailed surface cuts. Many operators appreciate the straightforward nature of these tools, particularly in industries where setup time must be lessd without sacrificing output precision. Their ongoing use in metalworking, aerospace components, and equipment fabrication shows a broad acceptance across technical environments.

As new materials and components emerge, the requirements for precise, clean cuts are expected to remain high. With their proven track record, both the High Performance Straight Shank Drill and the straight cutter tool continue to serve as reliable choices for production and prototyping. Their evolving designs suggest continued relevance in a manufacturing world that values both tradition and adaptation.

Language

Language  English

English 中文简体

中文简体 русский

русский

Contact Us