As the global machining industry continues to adapt to evolving production requirements, the demand for versatile hole-making tool solutions is increasing across various sectors. From aerospace components to general industrial parts, manufacturers are seeking tools that deliver consistent performance across a broad range of materials and machining conditions. This shift is influencing the development and adoption of both traditional and advanced cutting tools.

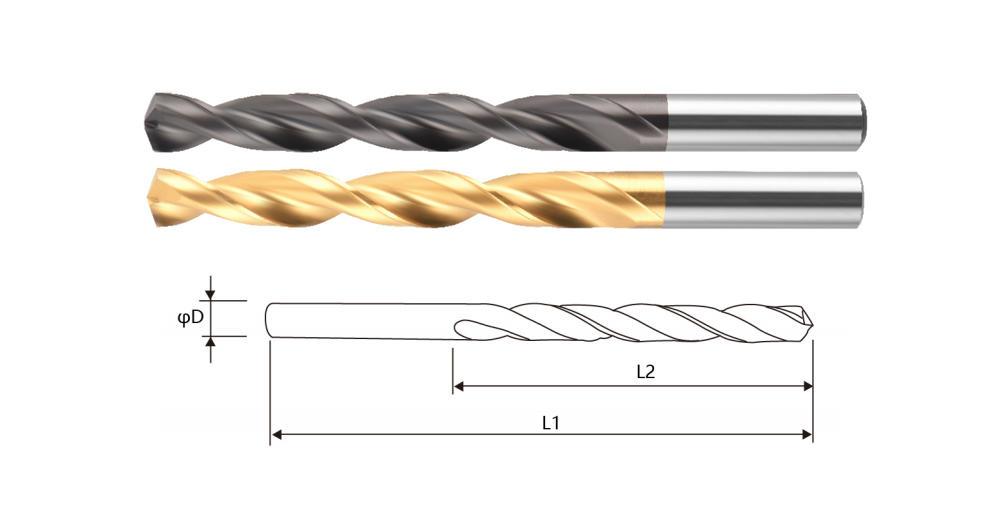

One key tool that remains widely used is the High Speed Steel Twist Drill. Known for its balance of toughness and cutting efficiency, this drill type remains a reliable choice in many hole-making applications. While more specialized tools exist for certain tasks, the High Speed Steel Twist Drill continues to serve a critical role in small to medium-scale operations where adaptability and cost-effectiveness are priorities.

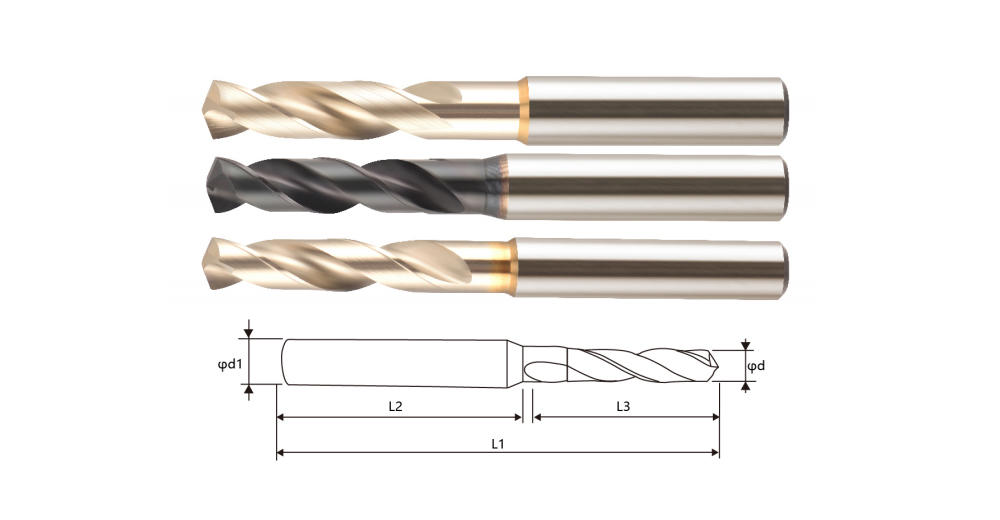

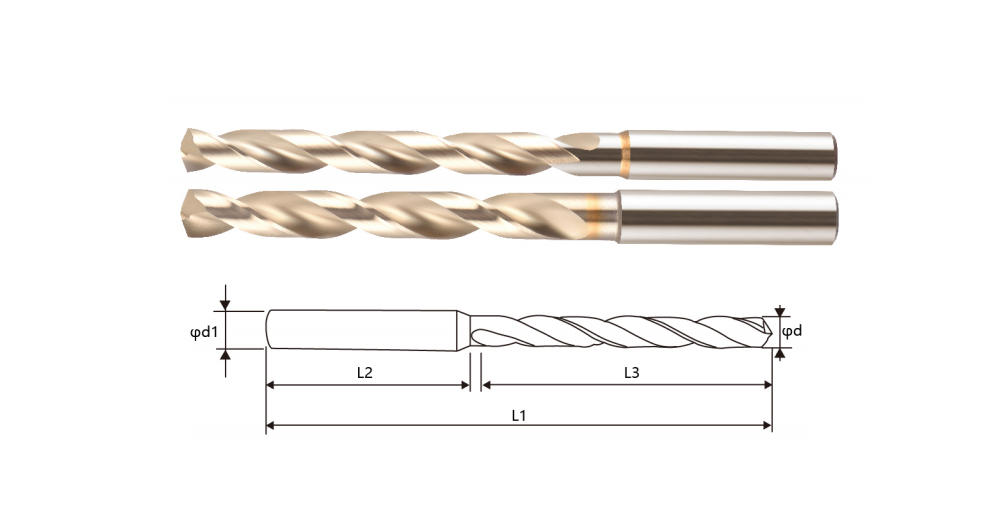

At the same time, manufacturers are showing increased interest in deep hole drilling tools, driven by a growing need for precision and depth in components like hydraulic cylinders, fuel systems, and injection molds. These tools are designed to maintain accuracy and chip evacuation efficiency over extended drilling lengths, making them essential in processes that exceed the capability of conventional drills.

The integration of CNC technology and more sophisticated production methods has led to a diversification in materials being processed. This, in turn, places greater demands on tool versatility. In response, many operations still rely on the High Speed Steel Twist Drill, especially when working with alloys, soft steels, and non-ferrous materials. The ability to resharpen these drills and extend tool life further adds to their appeal in cost-sensitive environments.

For operations requiring significant depth, deep hole drilling tools provide a reliable alternative to standard twist drills. These tools come in various forms, including gun drills and BTA (boring and trepanning association) systems, each designed to tackle unique depth and accuracy challenges. Industries involved in oil and gas, energy, and automotive manufacturing frequently utilize these tools to meet their specialized requirements.

Moreover, production managers are increasingly assessing tool flexibility when planning machining strategies. The High Speed Steel Twist Drill is often selected for jobs requiring quick changeovers or batch-based production, where tool versatility directly impacts throughput. It also proves useful in maintenance workshops and job shops, where varied workpieces are handled in limited volumes.

Similarly, deep hole drilling tools are now being incorporated into more flexible setups, including CNC machining centers that were once dominated by more general-purpose tools. This shift illustrates a growing appreciation for combining depth capabilities with broader machine integration. Tool designers are responding by refining geometries and developing new chip control methods that align with these modern expectations.

In addition to design enhancements, coatings and heat treatment processes are being applied to both High Speed Steel Twist Drill variants and deep hole drilling tools. These improvements help reduce wear and improve thermal resistance, extending tool life without compromising cutting performance. For many users, these upgrades offer a meaningful advantage in demanding production settings.

Environmental considerations also play a role in tool selection. Reusability and the ability to regrind or modify tools, such as the High Speed Steel Twist Drill, align well with sustainability goals. Likewise, the efficiency of deep hole drilling tools reduces cycle times and coolant usage, contributing to leaner operations.

In conclusion, the machining industry’s need for adaptable, durable, and efficient hole-making tools is driving renewed attention to both time-tested options and specialized solutions. The High Speed Steel Twist Drill remains a staple due to its versatility and cost value, while deep hole drilling tools continue to gain ground in applications requiring enhanced depth and precision. As manufacturing trends evolve, toolmakers and machinists alike will benefit from this expanding toolkit of hole-making strategies.

Language

Language  English

English 中文简体

中文简体 русский

русский

Contact Us