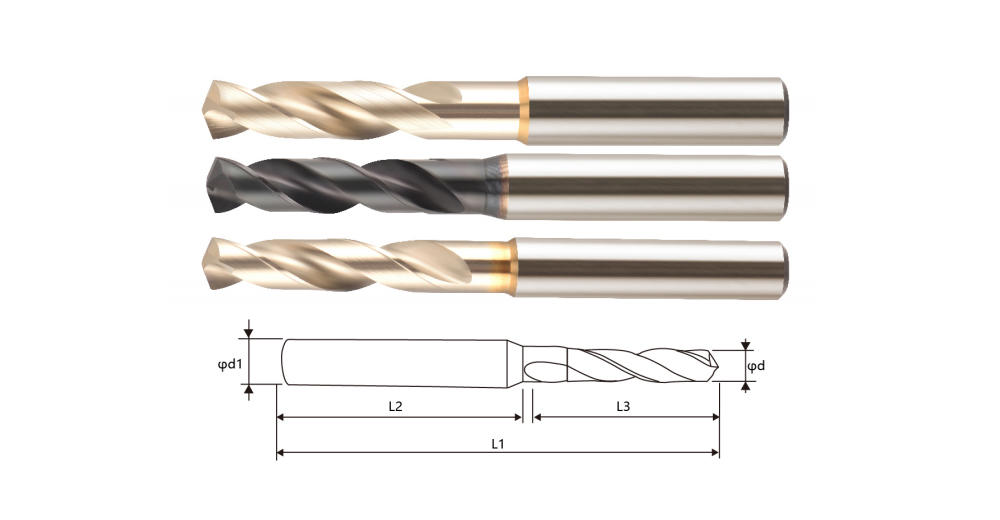

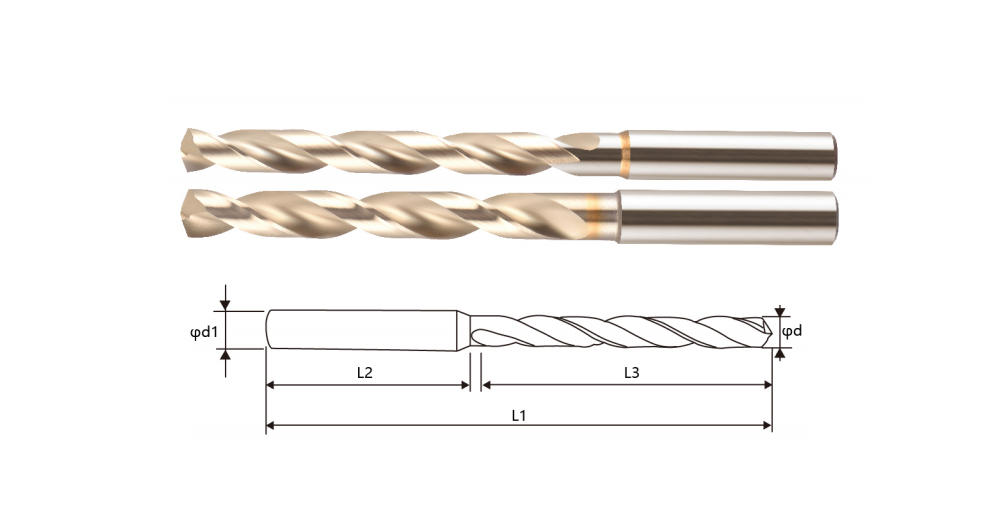

The demands of modern machining continue to evolve, pushing tool manufacturers and engineers to find new ways to extend tool life and maintain precision in hole-making operations. One of the key areas of development in recent years has been the improvement of wear resistance in twist drill applications, particularly through advanced coating technologies. This has had a noticeable impact on the performance and durability of both High Speed Steel Twist Drill products and deep hole drilling tools, which are essential in many manufacturing processes.

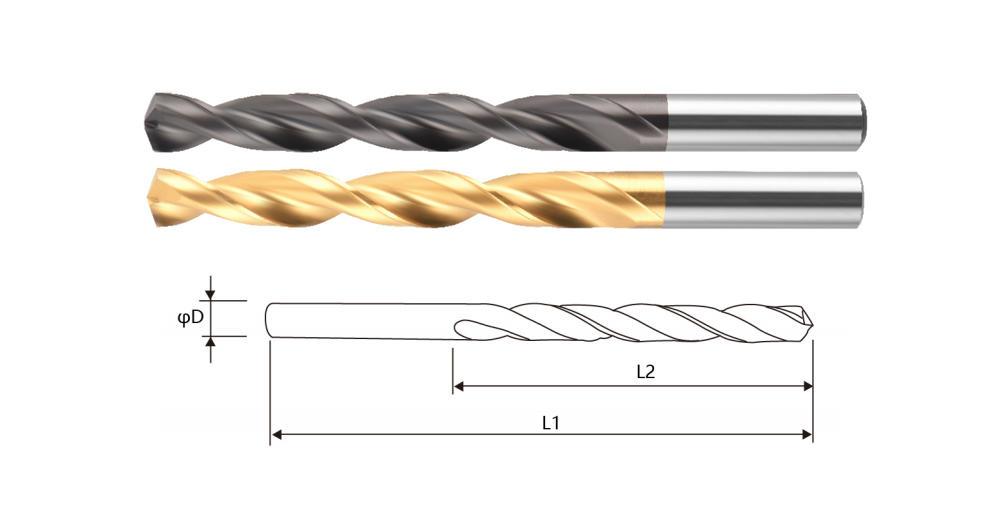

High-speed steel (HSS) continues to be a widely used material for drills due to its balance of toughness and affordability. However, in challenging machining environments—especially those involving harder materials or longer production runs—wear and heat buildup can limit the efficiency of a High Speed Steel Twist Drill. To address this, new surface coatings such as titanium aluminum nitride (TiAlN), diamond-like carbon (DLC), and chromium nitride (CrN) have been adopted. These coatings provide improved thermal stability and reduce friction, allowing High Speed Steel Twist Drill tools to maintain sharper cutting edges for longer periods.

One of the notable benefits of these coatings is the ability to reduce heat generation during cutting. Excessive heat can advance to premature tool failure, especially during high-speed or deep hole drilling tool applications where chip evacuation is more difficult. Coated drills are better equipped to handle the thermal stress, helping maintain performance over extended use. This has contributed to fewer tool changes and more consistent hole quality across workpieces, especially in steel, stainless steel, and composite materials.

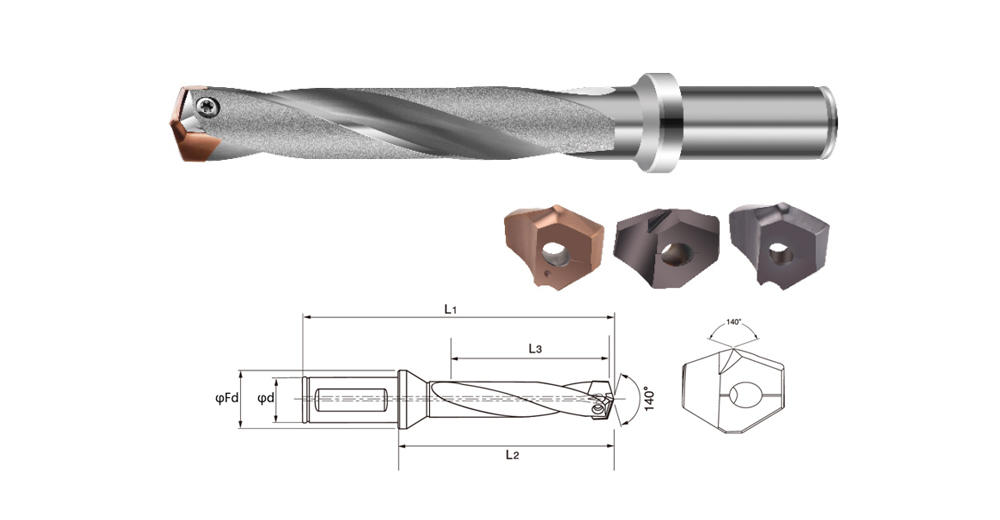

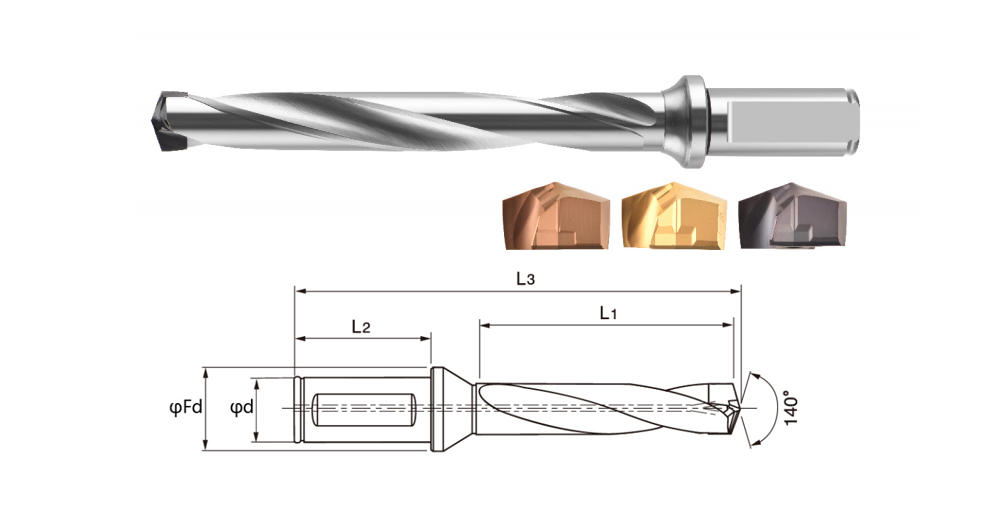

Coating advancements also play a significant role in increasing the versatility of deep hole drilling tools. Since these tools often operate under high axial loads and in limited-access areas, wear resistance is critical. By applying multi-layer coatings that combine hardness with lubricity, manufacturers have achieved notable reductions in flank wear and edge chipping. This means that deep hole drilling tools can now handle more aggressive feeds and speeds without compromising tool integrity.

The development of nanocomposite coatings has further expanded the performance range of hole-making tools. In particular, drills coated with nano-TiAlN have demonstrated significant improvements in wear control, particularly when used on CNC machines with consistent cooling systems. These coatings also support dry or less quantity lubrication (MQL) processes, offering more sustainable options without sacrificing tool life. As a result, the High Speed Steel Twist Drill remains relevant in various industries, including automotive, aerospace, and general metalworking.

Testing and performance analysis show that coating selection must be matched with the intended application. For instance, while TiN coatings are commonly used for general-purpose drilling, tougher applications benefit from TiAlN or AlCrN due to their ability to withstand higher temperatures. For deep hole drilling tools, where prolonged contact with the workpiece generates continuous wear, the right coating can make a substantial difference in tool longevity and performance consistency. These innovations enable manufacturers to meet tighter tolerances while less tool-related downtime.

Although the underlying cutting geometries of drills remain important, it is clear that coating technology has become a key factor in modern tool engineering. For a High Speed Steel Twist Drill, the right surface treatment can elevate its functional lifespan even in semi-automated or less rigid machining setups. This enables workshops and factories to make better use of existing equipment while ensuring consistent production quality.

As industries continue to demand higher productivity and lower operational costs, the integration of advanced coatings into deep hole drilling tools and other twist drill variants is expected to grow. By extending tool life and enhancing wear resistance, these coatings support more efficient and reliable machining practices. The evolution of the High Speed Steel Twist Drill into a more durable and heat-resistant tool demonstrates how materials science continues to shape the future of precision manufacturing.

Language

Language  English

English 中文简体

中文简体 русский

русский

Contact Us