The growing demand for efficiency and versatility in metalworking operations has brought renewed attention to the role of cutting tools. Among the equipment gaining traction across various sectors is the straight cutter tool, valued for its ability to perform stable and reliable operations. Alongside it, the High Performance Straight Shank Drill has shown a consistent presence in environments requiring consistent hole accuracy and compatibility with a broad range of materials.

In machine shops, the straight cutter tool is often used in milling processes, particularly where clean surface finishes and predictable tool paths are needed. Its straightforward design allows machinists to achieve accurate cuts with less setup complexity. These tools have found use in both automated CNC systems and manual machining tasks. At the same time, the High Performance Straight Shank Drill is regularly paired with these cutters in operations that require drilling prior to shaping or cutting a piece.

Automotive part manufacturing, where durability and repeatability are vital, continues to use the straight cutter tool in routine machining of components like brackets and casings. These cutters are suitable for alloy and carbon steels commonly used in vehicle parts. Complementing this, the High Performance Straight Shank Drill enables precise hole placement, especially important when parts will be fastened or assembled with small tolerance allowance.

The aerospace industry has also increased the use of these tools. Materials such as titanium and high-strength aluminum alloys, often used in aircraft components, require cutting instruments that can maintain consistency without excessive wear. A straight cutter tool can remove surface material effectively, while the High Performance Straight Shank Drill delivers reliable penetration depth even in difficult-to-machine alloys. Tool performance in these applications hinges on not just strength, but also the ability to dissipate heat and retain form under pressure.

In fabrication shops handling structural steel, aluminum panels, or other custom assemblies, the straight cutter tool assists in slotting, facing, and contouring workpieces. Its design offers predictable engagement with the work surface, helping avoid chipping or deflection. Following up with a High Performance Straight Shank Drill ensures that drilled holes maintain roundness and depth even on uneven or non-flat surfaces.

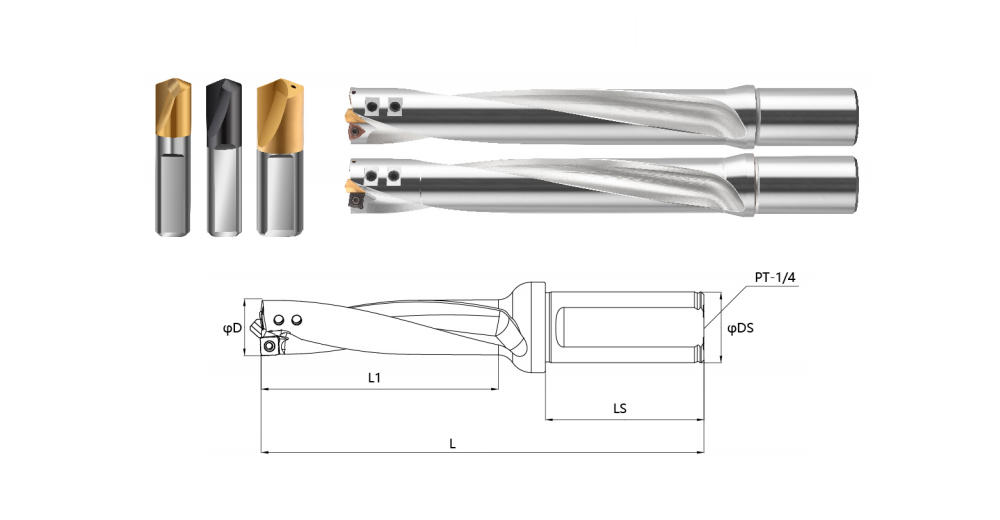

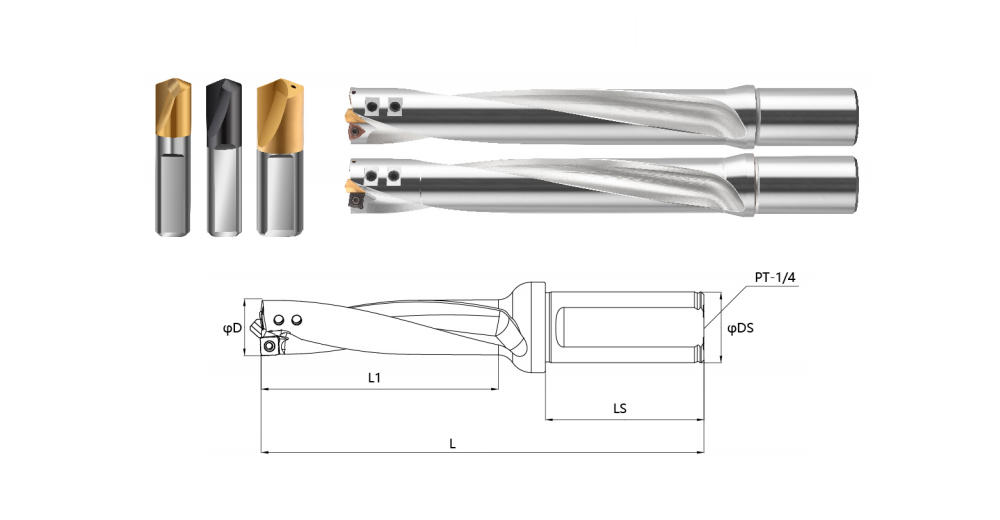

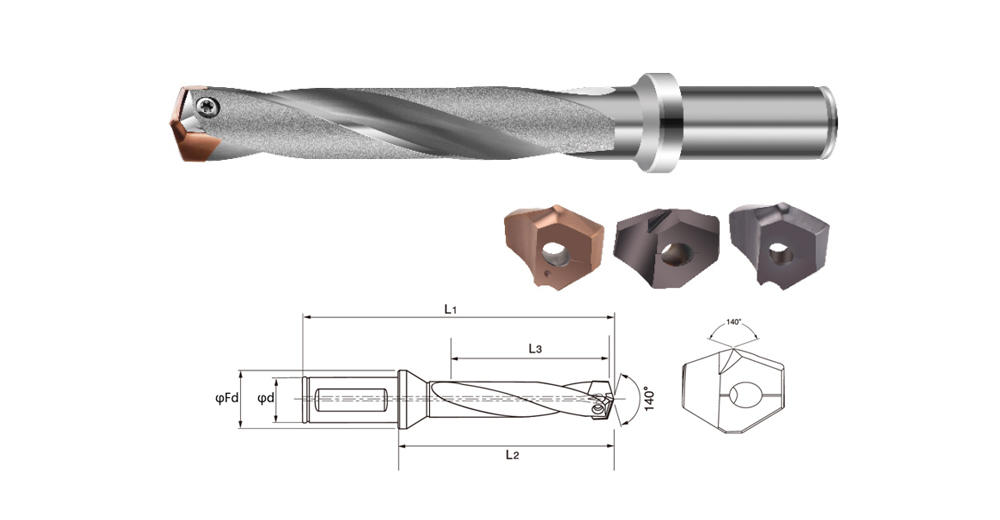

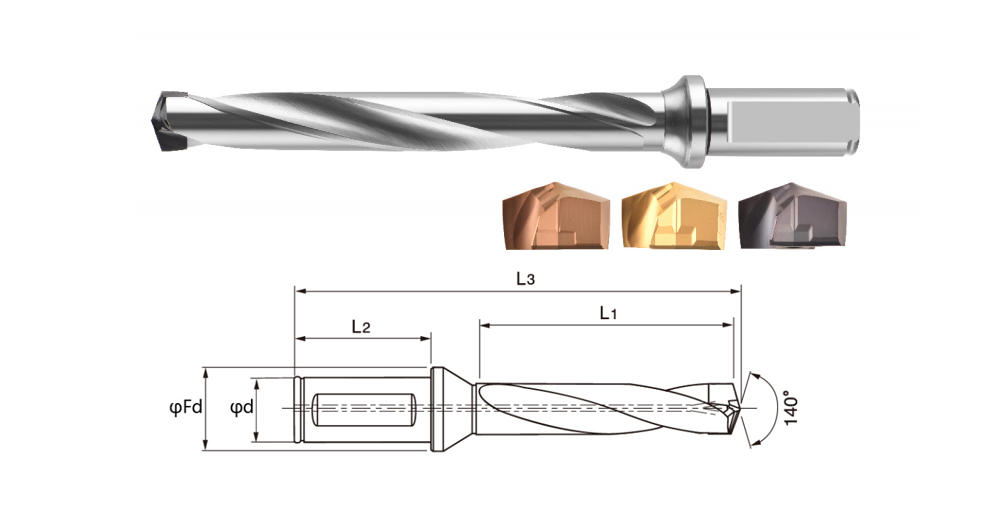

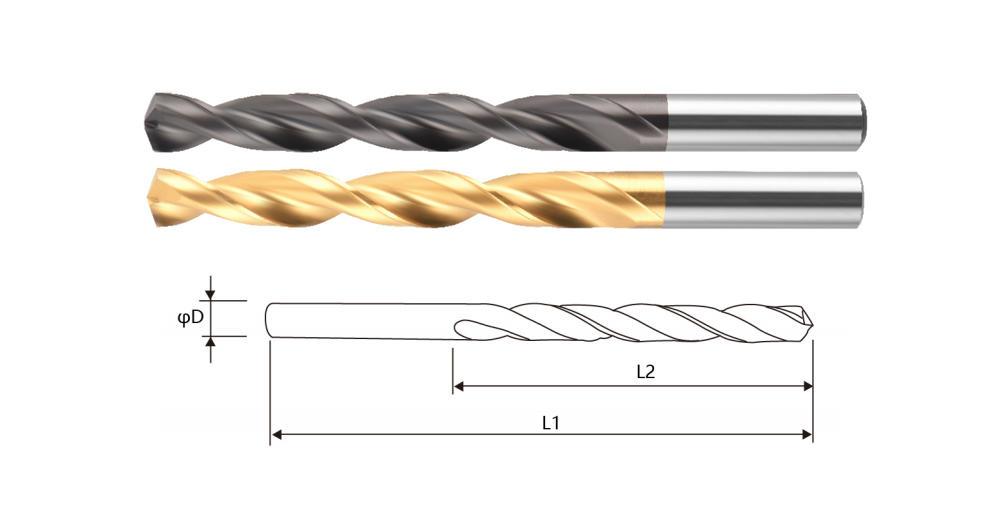

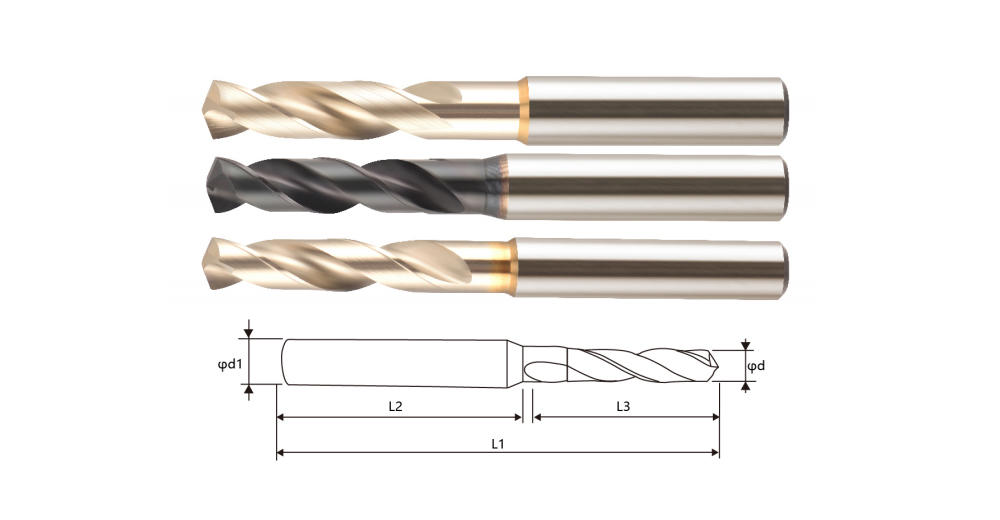

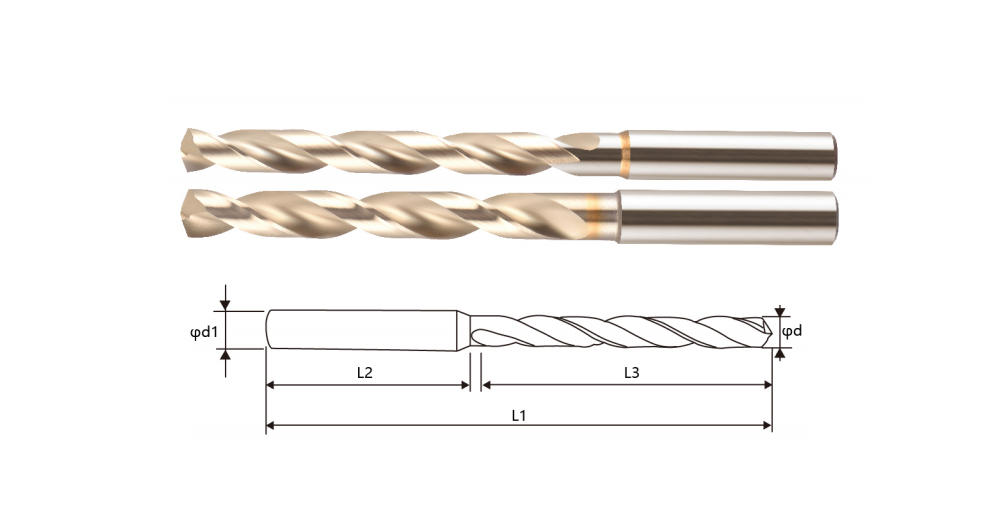

Tool manufacturers have responded to the broader usage trends by introducing variations of both tools with refined materials and coatings. For instance, some High Performance Straight Shank Drill models are now built with coated surfaces to reduce friction and extend tool life. Likewise, straight cutter tool variants are increasingly available with geometry tailored for specific feed rates and cutting conditions. These changes support industries aiming to reduce downtime and increase repeatability across production runs.

In workshops where custom tooling operations are frequent, the combination of a straight cutter tool and a High Performance Straight Shank Drill provides a flexible toolkit. They can be deployed together or independently, based on project requirements, with the ability to switch between high-speed cuts and precision hole drilling as needed. This pairing supports a workflow that balances cutting speed with dimensional consistency.

The presence of the straight cutter tool and the High Performance Straight Shank Drill across metalworking industries is a reflection of their functionality and adaptability. Whether in batch production, high-mix jobs, or custom fabrication tasks, these tools support a wide array of cutting and drilling operations without excessive complexity. Their role is likely to remain prominent as manufacturing sectors continue to seek practical tools suited to demanding conditions.

Language

Language  English

English 中文简体

中文简体 русский

русский

Contact Us